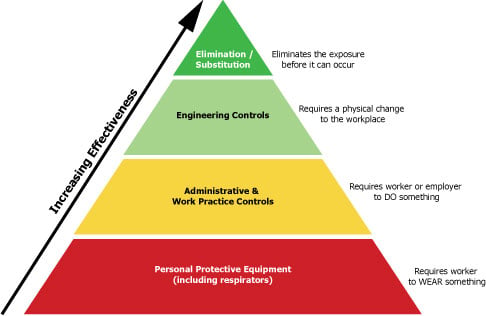

- Elimination/substitution. At the very top is the best way to deal with a safety hazard, which is to eliminate it altogether by preventing exposure to the hazard before it even occurs. In substitution, you seek to permanently reduce the risk by substitute a less hazardous material or reduction of system energy. These are process design solutions that require a permanent change to how a job is performed.

- Engineering controls. Change the structure of the work area to reduce exposure using safety devices or barriers. An example would be to place a high fence around a dangerous location to prevent access.

- Administrative & work practice controls. Implement procedures that require workers to do things to reduce their exposure to a risk. A lockout/tagout program is an example of an administrative control. Set expectations that workers will engage in safe work practices. Another example is the use of warning signs, sirens and alarms.

- Personal protective equipment (PPE). Make sure employees wear the proper protective clothing, gloves and eyeglasses for the job. Examples are safety goggles, respirators, fall protection and hearing protection.

It is easy when filling out Job Safety Analyses or Incident Investigation Reports to focus on the use of PPE and administrative controls because these are often the easiest to see and implement. But because these rely on human behavior, they are not always the best approaches to take. Safety professionals should look further up the pyramid to the higher order engineering solutions and risk elimination strategies, which can prevent the exposure to a risk before it occurs and reduce the risk without relying on fallible human behavior.

If you need more information about Safety Auditing, Safety Management Systems or want to outsource this work to a Safety Consultant, we have the services and information you need. Talk to us by completing a contact form and we'll be in touch.