Electrical Safety Testing

Electricity is used throughout the workplace, but it should never be underestimated when it comes to safety. Electricity powers the majority of equipment in offices, manufacturing, construction and almost every industry, but it should be respected for the dangers and hazards it poses to workers.

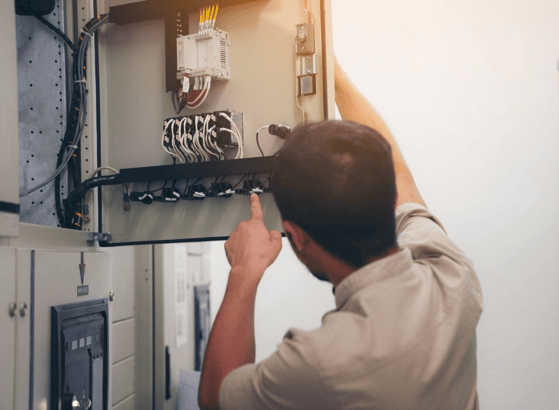

Workplace electrical safety applies to every business that uses electricity, but some workers are at higher risk for electrical injuries. When working with direct circuits for installing equipment or in construction, it is important to follow electrical safety protocols to the letter, including the “test before you touch” rule.

In 2019, there were 166 electrical workplace fatalities, the most since 2011. In addition to the fatalities, there were an estimated 1,900 serious workplace electrical injuries in private industry that required at least one day off of work to recover. Construction workers had the most electrical fatalities, but installation, utility, and repair workers are also at high risk. While many electrical safety protocols should be followed to reduce the risk of injury, one of the most important is to always assume that a circuit is live until it is tested. Turning off power is not enough – the “test before you touch” protocol should always be used before beginning a project involving an electrical circuit.

Test Before You Touch Steps

Turning off the power to a circuit does not mean it is safe. This is one of the basic rules of workplace electrical safety for anyone working with electrical circuits. While it seems simple, missing even one step in the process can lead to electrocution risks if there are components that are still energized when a project begins. The seven steps to the “test before you touch” safety protocol are as follows:

1. Plan Ahead

The first step is planning your project and make sure everyone involved is properly trained and qualified to work on the electrical equipment. Jumping into a project without a plan or the right personnel increases your risk of electrical injuries.

2. Identify All Potential Hazards

Know which circuits are connected to the equipment or in the areas where you will be working. Identifying all hazards should be part of the planning process.

3. Protect Yourself and Wear PPE

Everyone working in the area needs to protect themselves and others by wearing the correct PPE – hats, gloves, safety footwear, goggles, etc.)

4. De-Energize the Circuit

Shut off power to the circuit.

5. Use Lockout/Tagout Procedures

Follow the designed lockout and tag-out procedures to alert everyone to the potential risks and hazards.

6. Test the Circuit

Using an approved and verified electrical testing device, ensure the circuit has been de-energized.

7. Verify the Testing Device

The testing device should be checked before and after you use it to make sure it is working correctly.

Skipping any of the steps can be a deadly mistake. It is vital workers understand the importance of taking the time to plan the project and verify that a circuit is de-energized before beginning any task where they will be working with that circuit. Providing electrical safety training to all employees that includes an overview of the “test before you touch” protocol, required PPE, lockout/tag-out procedures, and other safety rules can reduce your risk of workplace electrical injuries.

At SafetyPro Resources, we are your source for safety training, management, staffing and programs to keep your workplace safe while protecting your bottom line. For more information on electrical safety and other workplace training for your company, contact our safety experts at our office in Baton Rouge, Louisiana.